Revolutionizing Metal Fabrication with **Stainless Honeycomb**: The Industry’s Ultimate Solution

Understanding the Significance of Stainless Honeycomb in Modern Industry

In the realm of high-end metal fabrication, materials that offer both durability and aesthetic appeal are highly sought after. Among these, stainless honeycomb stands out as a revolutionary component that combines strength, lightweight qualities, and versatile applications. Its unique hexagonal pattern, inspired by nature’s most efficient structure, provides unparalleled benefits in various industrial sectors such as aerospace, architecture, automotive, and filtration systems.

At Goldeco Steel, our specialization in metal fabricators ensures that we deliver premium quality stainless honeycomb products tailored to meet exacting industry standards. This comprehensive guide delves into the intricacies, advantages, manufacturing processes, and innovative applications of stainless honeycomb, establishing it as an indispensable element in advanced engineering and design.

What Is Stainless Honeycomb? An In-Depth Overview

Stainless honeycomb is a meticulously engineered metallic structure composed of interconnected hexagonal cells made from stainless steel. Its structure resembles a honeycomb pattern, which naturally offers optimal strength-to-weight ratios. This characteristic makes stainless honeycomb a preferred choice for applications where both strength and weight reduction are critical.

The primary composition involves various grades of stainless steel, commonly 304, 316, and 321, which provide corrosion resistance, thermal stability, and exceptional durability. These grades are selected based on the specific application requirements, environmental conditions, and mechanical loads.

Benefits of Using Stainless Honeycomb in Metal Fabrication

- Superior Strength-to-Weight Ratio: The hexagonal configuration offers maximum structural integrity without adding unnecessary weight, essential for aerospace and automotive industries.

- Excellent Corrosion Resistance: Thanks to stainless steel’s inherent properties, stainless honeycomb withstands harsh environments, chemicals, and moisture.

- Enhanced Heat Dissipation: Its structure facilitates efficient thermal management, making it ideal for heat shields and radiators.

- Acoustic and Vibration Absorption: The honeycomb design dampens sound waves and absorbs vibrations, improving comfort and product longevity.

- Customizable Design Flexibility: Fabricators can tailor cell sizes, thicknesses, and surface finishes to meet specific project demands.

- Eco-Friendly and Sustainable: The recyclable nature of stainless steel aligns with global sustainability goals, making stainless honeycomb a green choice.

Manufacturing Processes of Stainless Honeycomb: From Concept to Reality

The production of stainless honeycomb involves advanced manufacturing techniques to ensure precision, consistency, and high-quality output. The process typically includes:

1. Material Selection and Preliminary Cutting

Raw stainless steel sheets are carefully selected based on grade and thickness. These sheets are cut into manageable sizes for subsequent processes, ensuring minimal waste and optimal material usage.

2. Forming the Honeycomb Cells

The core of stainless honeycomb manufacturing involves embossing or slitting technique where the sheets are precisely patterned into hexagonal cells. This step requires high-precision machinery to achieve uniformity across large sheets.

3. Bonding and Stacking

Multiple honeycomb layers may be bonded together via welding or adhesive, depending on the application. For structural applications, laser welding ensures mechanical integrity without compromising corrosion resistance.

4. Surface Finishing

Post-formation, surfaces are finished through processes like polishing, passivation, or coating to enhance corrosion resistance and aesthetic appeal.

5. Quality Control and Testing

Extensive inspections, including dimensional checks, tensile testing, and corrosion resistance assessments, ensure that each stainless honeycomb product meets industry standards and client specifications.

Applications of Stainless Honeycomb in Industry

The versatility of stainless honeycomb allows it to be integrated into numerous high-performance applications, including:

Aerospace and Aviation

Lightweight, high-strength stainless honeycomb panels are widely used in aircraft flooring, interior panels, and thermal shields, significantly reducing weight while maintaining safety standards.

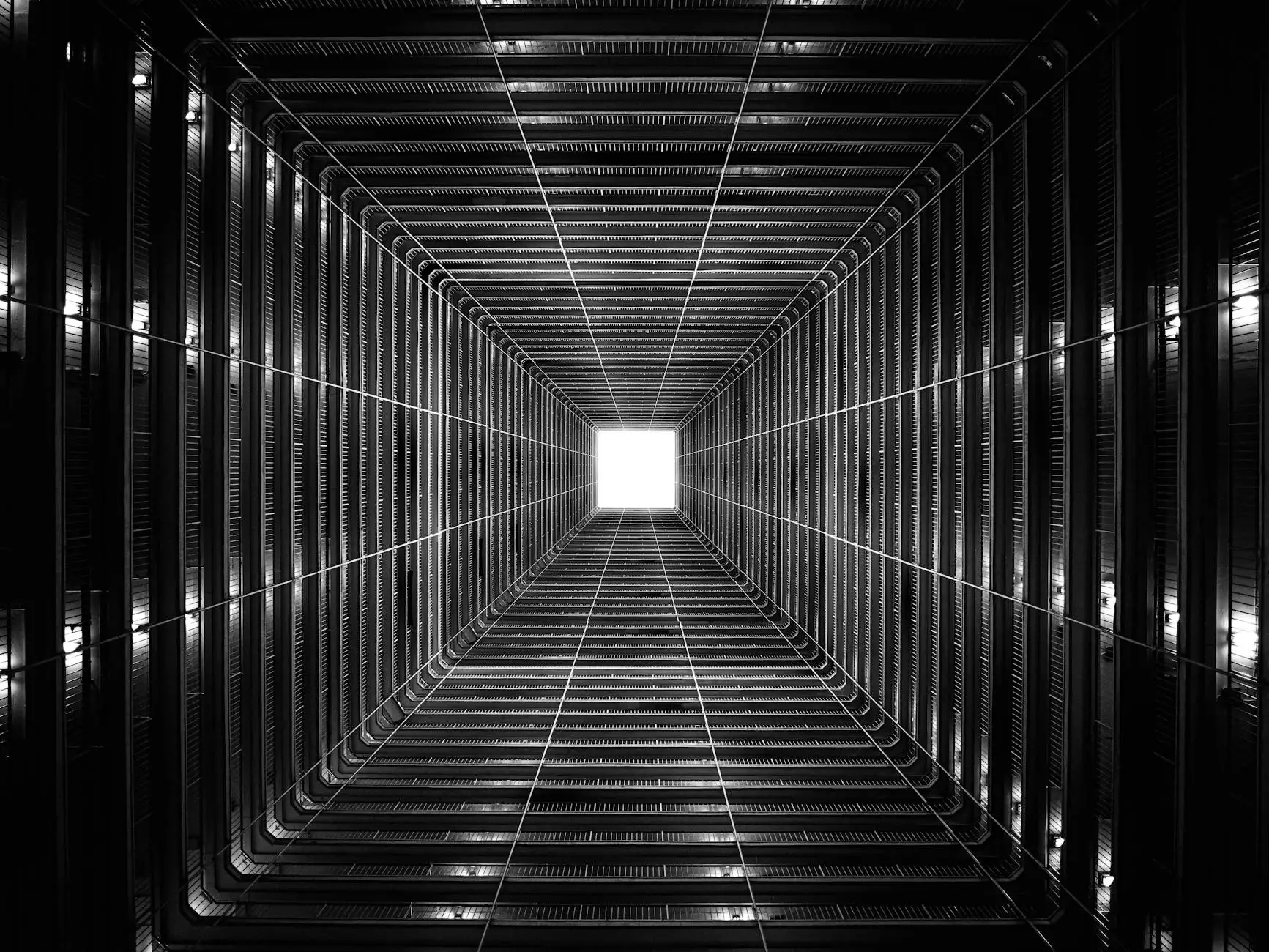

Architectural and Interior Design

Stainless honeycomb is employed as decorative wall panels, facades, and feature walls, imparting a modern, sleek aesthetic while providing durability against environmental elements.

Automotive Industry

In automotive manufacturing, stainless honeycomb structures are used in exhaust filters, heat exchangers, and lightweight vehicle body components to improve performance and fuel efficiency.

Filtration and Environmental Systems

Its porous yet sturdy structure makes stainless honeycomb an excellent medium for catalytic converters, air and water filters, enhancing filtration efficiency and durability.

Industrial Equipment and Heat Shields

Thanks to its thermal properties, stainless honeycomb is used in heat shields for industrial machinery, protecting sensitive components from excessive heat exposure.

Why Choose Goldeco Steel for Your Stainless Honeycomb Needs?

As a leading metal fabricator, Goldeco Steel combines expertise, advanced technology, and a commitment to excellence to deliver stainless honeycomb products that surpass client expectations. Here’s why partnering with us provides a competitive edge:

- Unmatched Quality Control: Our strict quality assurance process ensures each stainless honeycomb panel meets international standards.

- Innovative Manufacturing Techniques: We utilize state-of-the-art machinery for precision fabrication and custom designs.

- Customization Capabilities: Tailor your stainless honeycomb to specific dimensions, permittivity, and surface finishes.

- Eco-Conscious Approach: Our sustainable manufacturing practices align with global environmental commitments.

- End-to-End Service: From initial design consultation to final installation, Goldeco Steel provides comprehensive support.

Investing in the Future with Stainless Honeycomb Technology

In an era where performance, efficiency, and sustainability are paramount, stainless honeycomb stands out as a game-changer in the metal fabrication industry. Its ability to combine lightweight strength, corrosion resistance, and design flexibility makes it indispensable for cutting-edge projects worldwide.

Goldeco Steel’s expertise in metal fabricators ensures your stainless honeycomb solutions are crafted with precision, durability, and innovative spirit. By incorporating this advanced material into your manufacturing processes, you elevate your product offerings, optimize performance, and support sustainable development goals.

Contact Goldeco Steel for Premium Stainless Honeycomb Fabrication

If you are seeking high-quality stainless honeycomb components for your project, don’t compromise on expertise and quality. Trust Goldeco Steel, a reputed leader in metal fabrication, to deliver products that meet your specifications and exceed your expectations.

Our dedicated team is ready to assist with custom designs, technical consultations, and end-to-end fabrication services. Reach out today and discover how stainless honeycomb can transform your industrial applications and provide a competitive advantage in your market.

Conclusion: Embrace the Power of Stainless Honeycomb in Metal Fabrication

With its unmatched combination of strength, durability, and design flexibility, stainless honeycomb epitomizes the evolution of modern metal fabrication. By choosing Goldeco Steel as your trusted partner, you are investing in a solution that delivers innovation, sustainability, and superior quality.

As industries continue to push the boundaries of technology and efficiency, stainless honeycomb will undoubtedly play a pivotal role in shaping the future of engineering excellence. Embrace this advanced material and elevate your projects with Goldeco Steel’s expertise in metal fabricators specializing in stainless honeycomb manufacturing.